Solar Bracing Kits - How to Install

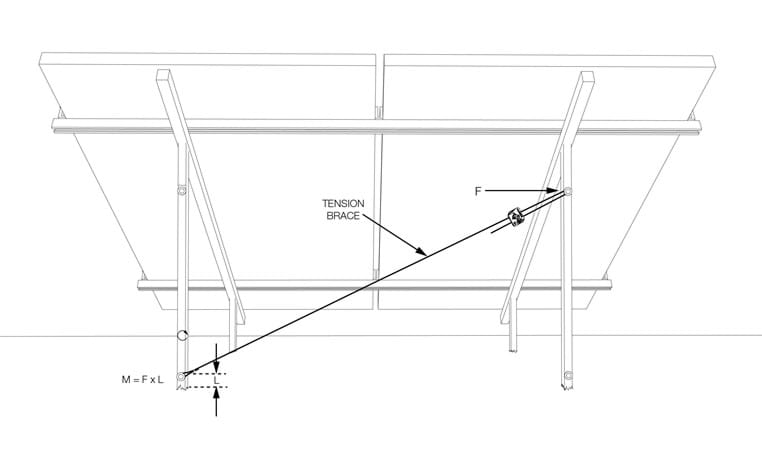

External loads, which are usually applied at the top of the structural legs, translate as a ‘moment’ at the base. The moments can often be quite large due to the length of the frames.

Our Solar Bracing Kit is designed to reduce the moments in steel frames – reducing the deflection and stress placed on the steel by transferring the force applied at the top of the structural legs into a reduced moment at the bottom. This allows engineers to decrease structural steel sections and foundations, delivering significant material savings whilst improving durability.

Installation Instructions - 45 degree eyelet

Step 1:

Fix eyelet end fixings to the frame.

Step 2:

Slide the Dynamic tensioner onto the loose end of the wire leaving around 1m of tail wire.

Step 3:

Pass the wire through the second eyelet and back through the Dynamic to create a loop, then pull hand tight.

Step 4:

Use the Torque Tool to apply the desired tension

Step 5:

Lock the Dynamic tensioner using the provided allen key.

Step 6:

Cut any excess wire or wrap the wire around the brace to avoid waste.

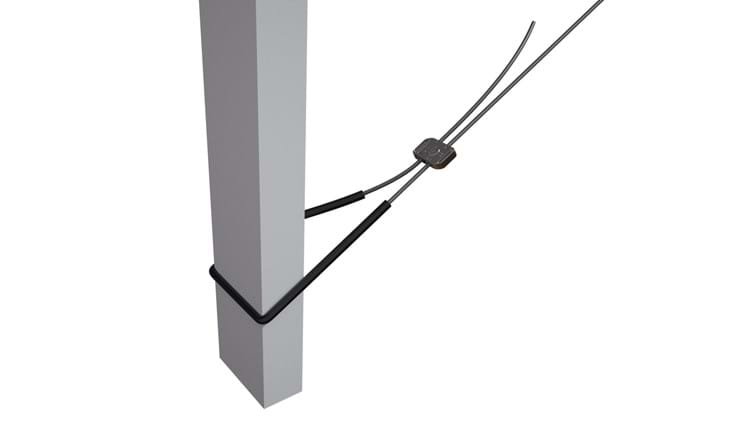

Installation Instructions - Loop

Step 1:

Add protective rubber tubing to the loose end of the wire and slide down to the loop.

Step 2:

Choke the loop end fixing around your fixing point or structure (using the protective tubing to stop abrasion).

Step 3:

Slide the Dynamic tensioner onto the loose end of the wire leaving around 1m of tail wire.

Step 4:

Add the second protective tubing to the loose end of the wire.

Step 5:

Pass the wire around the second fixing point or structure (using the protective tubing to stop abrasion) and back through the Dynamic to create a loop, then pull hand tight.

Step 6:

Use the Torque Tool to apply the desired tension.

Step 7:

Lock the Dynamic tensioner using the provided hex key.

Step 8:

Cut any excess wire or wrap the excess wire around the brace to avoid waste.

Why use Gripple?

- Significant time and cost savings on your project

- Complete, off-site solutions which minimise health and safety concerns

- Innovative, patented solutions designed by an in-house team of engineers

- Considerable reductions in packaging, vehicle movements & embodied CO2

- A range of support services at every stage of your project, provided by a dedicated technical team

- Aesthetically pleasing solutions; lightweight and virtually invisible