Myths about MSS SP-58 Compliance for Building Services Piping (MEP Piping) Installation

We often get the question; “Do cable hangers comply with MSS SP-58 or not?”

The answer is: Yes, you can use cable hangers such as Gripple for your piping and plumbing suspension requirements, as long as they have ICC-ES Certification. Read full report below or click here to download the PDF Version.

1. MSS SP-58 is written around threaded rod hanging methods, and is not a correct standard to evaluate cable hangers.

Cable hangers cannot be judged with MSS SP-58.

2. It is not mandatory for pipe hangers to prove compliance with MSS SP-58.

MSS SP-58 is not a code requirement for Building Services piping. Building Services piping needs to comply with the building codes of the states in which that building is located. All the piping

installation requirements within U.S. state codes are based on International Plumbing Code, Uniform Plumbing Code, and International Mechanical Code. None of these codes mandate a compliance

with MSS SP-58 requirements.

3. Compliance with IBC and State building codes is a must, and Gripple hangers meet this requirement through ICC-ES Certification.

National and State code compliance for piping installation can be achieved through two steps:

- Make sure to follow pipe support spacing as recommended by your local, state, or U.S. National Building Code.

- Make sure that the pipe support hardware you use is compliant with National / State Building Codes.

Gripple Cable Hanger system and Pipe Support system products are reviewed and certified by the Product Evaluation Service of International Code Council (ICC-ES) for compliance with National and State Building Codes. A piping installation made with Gripple products following the National / State Building Code recommended support spacing meets U.S. National and State Building Codes. For more information, contact your local Gripple Territory Manager or Gripple Inc. Technical Department.

Note: Piping installations may have additional code requirements depending on the region of the country where they are being installed. For example, piping installed within Seismic Design Category C through F have seismic bracing requirements. It is the designer’s responsibility to ensure a piping installation meets all the National, State and local Building Code requirements.

4. MSS-SP-58 is not the best standard for HVAC & Plumbing Piping in building applications, and can lead to overdesign as well as building code violation in certain cases.

4.1 Compliance with National Building Codes, but a system overdesign with added cost.

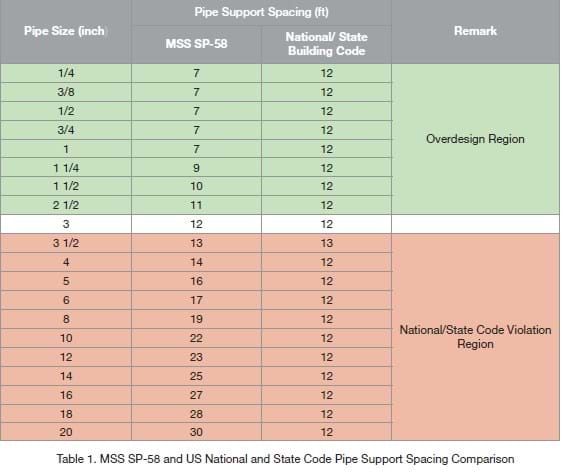

If you follow support spacing as recommended by SP-58, then piping installations with pipe sizes up to 3 inch will comply with National Building Codes. However, the recommended support spacing by MSS SP-58 is smaller than that is recommended by IPC, UPC, IMC, and all the state codes. The resulting installation will comply with the code, but will lead to an excessive number of hangers and support hardware than required by national codes.

The reason why SP-58 support spacing for these pipes is smaller is because SP-58 is a standard that is developed for the piping having the most conservative design requirements, i.e. Power Piping. Power Piping involves high pressure and temperature piping that is found within steam power plants and other industrial facilities. However, the piping found within buildings has relatively lesser design requirements than Power Piping. National Building Codes understand this, and the support spacing recommended within IPC, UPC, and IMC is more appropriate for building MEP Piping and saves a significant amount of material and labor.

4.2 National and State Building Code Violation.

If you follow pipe support spacing as recommended by MSS SP-58, then piping installations with pipe sizes above 3 inch will violate National and State Building Codes, because for these pipe sizes

National and State Building Codes call for shorter support spacing than is recommended by MSS SP-58. A National and State Building Code violation is generally interpreted as a violation of the

state or federal law.

Above points 4.1 and 4.2 are summarized in the Table 1 below comparing the support spacing requirements of SP-58 and National / State building codes

5. Gripple cable hangers do comply with the intent of MSS SP-58.

MSS SP-58 specifies compliance with ASME B31 standards as a general requirement for piping design. Gripple cable hangers are reviewed independently by a reputable third-party product

evaluation agency like ICC-ES, and are certified for compliance with ASME B31.9 Standard for Building Services Piping. Hence, by being compliant with a standard that forms the basis for MSS

SP-58, we can say that Gripple hangers do meet the intent of MSS SP-58 with regards to the piping that falls under the scope of ASME B31.9, which is HVAC and Plumbing Piping seen within buildings.

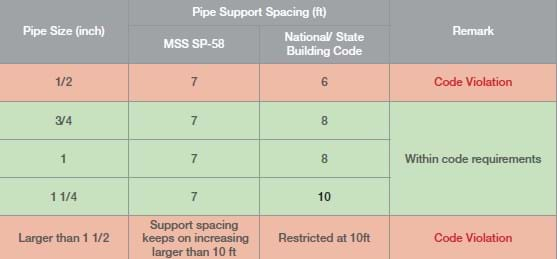

Appendix A: Fuel Gas Piping

Fuel Gas piping within buildings is governed by International Fuel Gas Code (IFGC 2018). With regards to the support spacing, IFGC 2018 makes its own support spacing requirements which are more stringent than MSS-SP 58 and following SP-58 support spacing can lead to code violation in certain instances. Below is the comparison of support spacing as recommended within SP-58 and IFGC 2018.

Gripple cable hangers are certified by ICC-ES for compliance with International Fuel Gas Code (IFGC 2018) and can be safely used on fuel gas piping in non-seismic regions, i.e. seismic design category A & B jobs. To use cable hangers on fuel gas piping in seismic regions, i.e. SDC C, D, E & F jobs, additional care is required and some special measures need to be implemented following an engineering analysis to ensure safety and compliance with building codes. Contact the Gripple Inc. Technical Department for more information on this subject.

Disclaimer: The intent of this document is to clarify some of the misconceptions related to codes and standards applicable to the piping within buildings governed by the International Building Code (IBC). Piping installations may have additional requirements based on local codes, service requirements, pipe and installation hardware capacities, etc. and this document shall not be considered as a replacement for an expert engineering analysis and judgement. It is the installer’s / piping system designer’s responsibility to ensure that their installation meets all the necessary building codes and design requirements.

Why use Gripple?

- Innovative, patented solutions designed by an in-house team of engineers

- Considerable reductions in packaging, vehicle movements, and embodied CO2

- A range of support services at every stage of your project, provided by our technical team.

- A range of support services at every stage of your project, provided by a dedicated technical team