Solar Bracing Kits

Our lightweight bracing kits provide comparable structural performance to heavy steel bracing, at a fraction of the cost.

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

Stainless Steel Hangers and architectural suspension system extreme environments.

Single point hanger with double hanging points to improve stability

Supporting solution to Gripple hanging systems where heavy loads need to be suspended such as heavy piping.

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

Stainless Steel Hangers and architectural suspension system extreme environments.

Single point hanger with double hanging points to improve stability

Supporting solution to Gripple hanging systems where heavy loads need to be suspended such as heavy piping.

Designed for architectural lighting suspensions, signage, acoustic baffles and all other installations where aesthetics are important

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

Single point hanger with double hanging points to improve stability

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

Stainless Steel Hangers and architectural suspension system extreme environments.

Supporting solution to Gripple hanging systems where heavy loads need to be suspended such as heavy piping.

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

Stainless Steel Hangers and architectural suspension system extreme environments.

Supporting solution to Gripple hanging systems where heavy loads need to be suspended such as heavy piping.

A seismic cable bracing restraint system designed to secure non-structural equipment with a wire size of 2mm during seismic events.

A Seismic cable bracing restraint system designed to secure non-structural equipment with a wire size of 3mm.

A seismic cable bracing restraint system designed to secure non-structural equipment with a wire size of 4mm.

A seismic cable bracing restraint system designed to secure non-structural equipment with a wire size of 5mm.

Stainless Steel Hangers and architectural suspension system extreme environments.

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

Designed for architectural lighting suspensions, signage, acoustic baffles and all other installations where aesthetics are important

A versatile cable suspension system for mechanical & electrical services from different substrates. A ready-to-use wire hanging kit.

Designed for architectural lighting suspensions, signage, acoustic baffles and all other installations where aesthetics are important

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

Designed for architectural lighting suspensions, signage, acoustic baffles and all other installations where aesthetics are important

A visually discreet suspension solution designed specifically for catenary system installations or bracing applications.

A time & labour saving method of geotechnical engineering for erosion control, soil retention & slope reinforcement.

The high load ground anchoring pin is designed to hold all types of turf reinforcement matting, erosion control blankets, geotextiles and landscaping fabrics.

Designed to secure and enhance geocell performance in slope reinforcement and soil retention applications.

A corrosion resistant underground ground anchor for easy installation into a wide variety of soils.

Self-sealing anchoring system for the protection of geomembranes; prevents membrane movement in uplift or draw down applications

A corrosion resistant underground ground anchor for easy installation into a wide variety of soils.

A time & labour saving method of geotechnical engineering for erosion control, soil retention & slope reinforcement.

A unique bracing solutions for both wooden end post bracing and metal end post bracing.

The Gripple Plus Anchor Kit for metal posts includes a pre-cut, fused length of wire rope, a Gripple tensioner and all the accessories needed to protect the anchoring wire.

Wire joiners for the patching and tensioning of all types and sizes of wire fencing.

For the fast termination of trellising wire, for use with metal end posts in orchard and vineyard trellising or fencing applications

A corrosion resistant underground ground anchor for easy installation into a wide variety of soils.

A simple and fast solution to securing trellising wires to concrete end posts in Viticulture, Orchard, and Fencing applications.

Ideal for high load trellising applications. fitted with larger ceramic rollers and heavy duty housing.

Supplied with wire and Gripple joiners and tensioners as a total trellising solution.

High strength, low elongation wire with specialised zinc aluminium coating, supplied as part of total vineyard solution.

Made to create overhead structures for cloth / net support, crop / down wires or fruit canopies.

The Gripple Plus Anchor Kit for metal posts includes a pre-cut, fused length of wire rope, a Gripple tensioner and all the accessories needed to protect the anchoring wire.

A corrosion resistant underground ground anchor for easy installation into a wide variety of soils.

A simple and fast solution to securing trellising wires to concrete end posts in Viticulture, Orchard, and Fencing applications.

A unique bracing solutions for both wooden end post bracing and metal end post bracing.

A fast, easy and secure method of structural anchoring or bracing in fencing and trellising applications

For the fast termination of trellising wire, for use with metal end posts in orchard and vineyard trellising or fencing applications

Wire joiners for the patching and tensioning of all types and sizes of wire fencing.

Ideal for high load trellising applications. fitted with larger ceramic rollers and heavy duty housing.

Wire joiners for the patching and tensioning of all types and sizes of wire fencing.

The quick & easy way to tie-off at the start or end of a fence or end post in Viticulture, Orchard and Fencing applications.

A large diameter wire joiner, allowing for steel wire patching & wire tensioning in fencing applications.

A fast, easy and secure method of structural anchoring or bracing in fencing and trellising applications

Ideal for high load trellising applications. fitted with larger ceramic rollers and heavy duty housing.

A corrosion resistant underground ground anchor for easy installation into a wide variety of soils.

A unique bracing solutions for both wooden end post bracing and metal end post bracing.

For the fast termination of trellising wire, for use with metal end posts in orchard and vineyard trellising or fencing applications

A ready-to-use wire fence brace kit.

No investment can be completely risk free, however, all good investors will take steps to manage and reduce risk. The same can be said for utility solar farms, and with ever bigger sites being commissioned the level of exposure for developers is becoming greater and greater.

Extreme weather as well as other external forces can lead to costly damage, and the bigger the site the bigger the risk.

Taking the Mohammed bin Rashid Al Maktoum Solar Park in UAE as an example, an eyewatering investment of $13.6 billion has been made to develop the site. With investment on this scale, protecting your assets from external forces becomes vitally important.

One simple and effective way to reduce the risk posed by external forces is to ensure bracing is installed on solar frames.

According to a report by renewable energy insurance specialist, GCube1, severe weather events are the cause of most solar insurance claims. But while severe weather is inevitable in some locations and increasingly common in others, catastrophic losses need not become the norm.

No site can be 100% risk free, but EPCs and developers can take action to minimise risk. Structural bracing is one key measure that can lead to huge cost savings by preventing or reducing structural damage.

Prevent stresses from external forces

Bracing is a well-established engineering technique, commonly used in the construction of steel frames to resist and prevent stresses from external forces such as wind and seismic activity.

By applying bracing solutions which are engineered to improve the stability and strength of your solar applications, you can avoid the damage and losses that can commonly occur on solar developments.

What forces are you up against?

Cost implications

The damage caused by these external forces can cause significant problems for solar power plants, both in terms of repairs and replacements, as well as production outages.

Even slight movements to the frame can cause micro-cracks in the panels which can lead to power losses of up to 33 per cent.

Although anecdotal studies show that the typical power loss is between 0% - 2.5%, even this is significant enough to eliminate profits or greatly increase the payback period for the solar farm.

Many sites use Tracker systems which tilt to follow the movement of the sun. These are also vulnerable to external forces, either through damage, or through power outages preventing the frame from following the sun’s path. In both instances, yield will be impacted, which will again reduce profits.

In high-risk areas, insurance costs can also be significantly higher. With some providers this increase can be mitigated by taking preventative measures, such as bracing.

How bracing can help

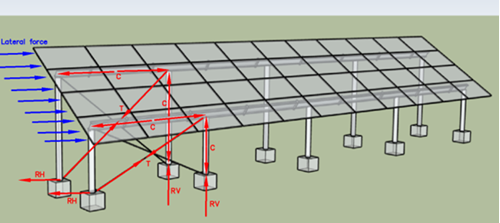

Bracing is commonly used in the construction of steel frames to resist external forces. Tension-only bracing is efficient and effective as it utilises the high tensile capacity of slender steel sections or wire rope. By resolving the lateral forces into a tensile force, the bending moments within the frame members are reduced.

Bracing is also effective at reducing the lateral movement of the top chord by restraining it back to the foundation points. Excessive lateral movement can cause increased strain in the solar modules, resulting in the formation of micro-cracks which can negatively affect their performance and lead to failure.

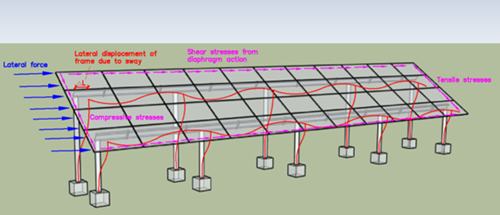

With no bracing system in place, the frame will resist lateral forces through a combination of sway in the vertical members and diaphragm action through the modules. This creates internal stresses within the plane of the solar module, causing micro-cracks to form.

Figures 1 and 2 show how braced and unbraced frames respond to lateral forces.

Figure 1. Unbraced solar frame

Figure 2.Braced solar frame

Reduce the risk of damage

Clearly, the risks to solar power plants from external forces are incredibly high and can lead to devastating losses. To protect their assets, EPCs and developers should look to mitigate risk through bracing, which is a simple and inexpensive way to minimise damage from external forces.

At Gripple, we offer a range of lightweight solar frame bracing kits which offer the same high performance as heavy steel bracing, at a fraction of the cost.

Our PV Solar Bracing Kit is designed to reduce the moments in steel frames - reducing the deflection and stress placed on the steel by transferring forces applied to the top of structural legs into reduced moments at the bottom.

The kit comes with protective tubing to reduce stress on the wire and PV racking system. A bracket can be supplied alongside the kits, so the kit can be seamlessly integrated into any system design.

The kits are simple and quick to install on site using just hand tools, with minimal training and are easy to handle compared to heavy steel sections.

As a business, we have been developing and manufacturing high quality bracing systems for over 30 years. Our innovative kits are tried and tested in critical infrastructure projects around the globe, including airports, highways, power plants and major construction developments.

Our new lightweight wire rope bracing kits can use just 7% of the steel compared with traditional steel bracing and have been tried and tested in demanding seismic, civil and blast protection applicat

Our lightweight bracing kits provide comparable structural performance to heavy steel bracing, at a fraction of the cost.

22 June 2023

Our lightweight bracing kits provide comparable structural performance to heavy steel bracing, at a fraction of the cost.